- Overview

- Suspendisse Products

It serves as the framework for assembling the external structural components of the transformer.Meanwhile, the heat generated by the losses of the transformer body is dissipated into the atmosphere in the form of convection and radiation through the transformer oil. The material of the transformer oil tank is usually made of steel plates.

As a container for holding insulating liquid, it has a sealed structure without leakage and can withstand a certain positive pressure.

The no-leakage condition includes:

①Neither the steel plate material nor the welding wire should have leakage, which depends on the uality of the steel plate material, the specification of the welding process, and the design of the welding structure.

② The sealed parts of the mechanical connection should not have leakage, which depends on the performance of the sealing material and the rationality of the sealing structure.

As the outer shell and framework, it should possess a certain mechanical strength,mainly including:

① It can bear the weight of the transformer body and the insulating liquid, as well as the overall lifting weight.

② It can support all the accessories of the transformer (such as bushings, oil conservators, radiators, etc.).

③ Itcan withstand the impact of acceleration during transportation and the action of seismic forces or wind loads under operating conditions.

④ For large transformers, the transformer body needs to be vacuum oil-filled inside the oil tank. Or when it is installed or repaired on site, the oil tank should be used to dry the transformer body. All these require the oil tank to be ableto withstand the atmospheric pressure during the vacuum-pumping process.

⑤ It should be ensured that it will not burst in case of internal faults of the transformer.

As a heat dissipation component, the structural form of the oil tank changes with the increase of the transformer capacity. Small transformers generate less heat, and the heat dissipation on the surface of the oil tank alone can meet the requirements. After the capacity increases, since the electromagnetic loss is proportional to the 3/4 power of the capacity,while the increase of the surface area is proportional to the 1/2 power of the capacity, that is, the rate of increase of the loss exceeds the rate of increase of the natural cooling surface area of the oil tank surface. Measures need to be taken in the structure of the oil tank to increase the heat dissipation area, such as adding heat dissipation flat tubes or designing the tank wall in a corrugated shape, etc.

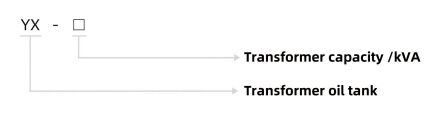

Typus descriptio

euismod parametri

| captum | Long | Slice number | Wave pitch | High | Inside length x Inside width x Inside height | Magnitudo pedis | Gauge magnitudine |

| 50 | 727 | 8 | 80 | 400 | 700x270x585 | 50x37x4.5 | 400x400 |

| 297 | 3 | ||||||

| 80 | 797 | 9 | 80 | 500 | 770x295x630 | 50x37x4.5 | 400x400 |

| 100 | 322 807 |

3 12 |

60 | 500 | 700x305x665 | 50x37x4.5 | 400x400 |

| 332 | 5 | ||||||

| 125 | 802 | 15 | 50 | 500 | 775x300x695 | 50x37x4.5 | 550x550 |

| 327 | 5 | ||||||

| 160 | 832 | 15 | 50 | 500 | 805x310x715 | 50x37x45 | 550x550 |

| 337 | 5 | ||||||

| 200 | 887 | 16 | 50 | 600 | 860x330x750 | 50x37x4.5 | 550x550 |

| 357 | 6 | ||||||

| 250 | 917 | 7 | 50 | 600 | 890x345x780 | 80x43x5 | 550x550 |

| 372 | 6 | ||||||

| 315 | 972 | 18 | 50 | 600 | 945x360x845 | 80x43x5 | 550x550 |

| 387 | 6 | ||||||

| 400 | 1017 | 19 | 50 | 600 | 990x375x885 | 80x43x5 | 550x550 |

| 402 | 7 | ||||||

| 500 | 1047 | 20 | 50 | 700 | 1020x390x925 | 80x43x5 | 660x660 |

| 417 | 7 | ||||||

| 630 | 1127 | 21 | 50 | 700 | 1100x420x970 | 80x43x5 | 820x820 |

| 447 | 8 | ||||||

| 800 | 1181 | 22 | 50 | 800 | 1150x440x1020 | 80x43x5 | 820x820 |

| 471 | 8 | ||||||

| 1000 | 1191 | 23 | 50 | 800 | 1160x450x1060 | 80x43x5 | 820x820 |

| 481 | 8 | ||||||

| 1250 | 1251 | 24 | 50 | 800 | 1220x465x1105 | 100x48x5.3 | 820x820 |

| 496 | 9 | ||||||

| 1600 | 1266 | 24 | 50 | 900 | 1235x470x1210 | 100x48x5.3 | 820x820 |

| 501 | 9 |